Statistical Process Control

As an essential part of its robust Quality Assurance program, MedFab utilizes Statistical Process Control (SPC) to monitor and optimize operations for maximum quality and efficiency in production.

How It Works & Why We Use It

Statistical Process Control is all about consistency. Using statistical data collected by continuously monitoring production processes, SPC lets MedFab technicians identify production and performance anomalies in real time, highlighting issues at the outset, often before they can adversely affect quality.

Multipoint Data Collection

SPC collects data from various points in the production process. It measures parts and components at varying stages of completion, gathers information on the efficacy of the processes themselves, tracks machine use and tool wear, and performs a host of other functions to obtain a comprehensive assessment of our production process in real time.

SPC measures and tracks a wide range of metrics to gage the quality of the part being produced and the overall health of the equipment producing it. SPC functions give real-time values for:

- Dimensions

- Volume

- Surface Finishes

- Alignments

- Geometries

- Machine Uptime

- Tool Wear

- Process Capability

- Repeatability & Reproducibility

- First Article Inspections

- Attribute Data

- Variable Data

Putting the Data to Use

By monitoring processes at all times, SPC generates a considerable amount of data, including precise measurements of part dimensions, process readings, and more. This trove of information is continuously processed and analyzed to identify any changes or irregularities in performance. Some of the problems SPC pinpoints include:

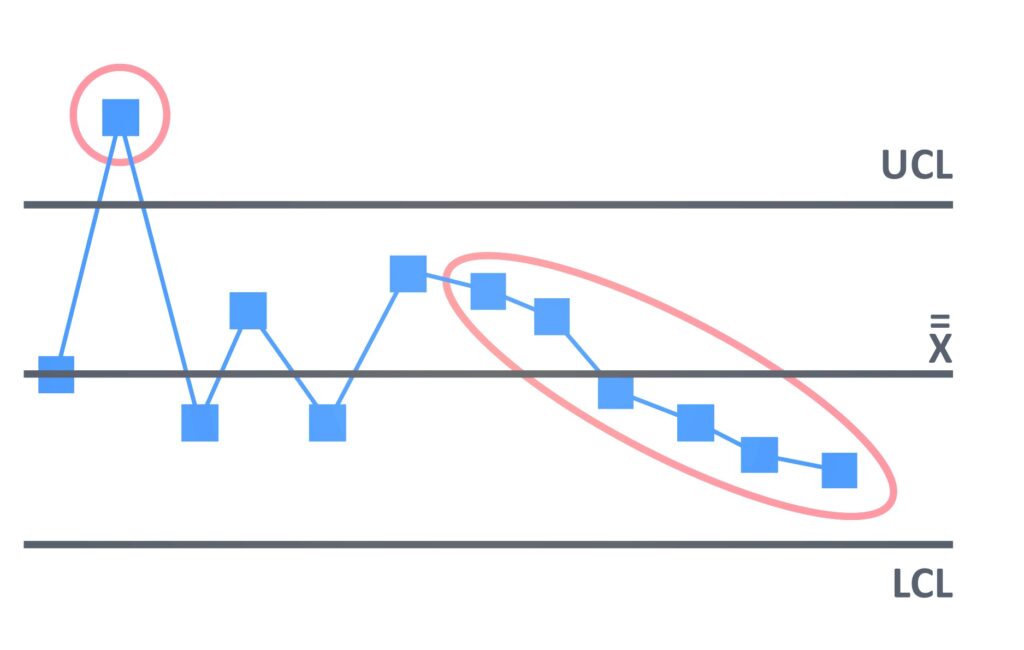

Variations–SPC can detect significant variations in process metrics instantaneously, facilitating earlier corrective intervention.

Process Shifts–SPC can detect when the average output deviates from target values.

Non-Random Patterns–By depicting data as points on a chart, SPC readily shows problems as clusters, lines, or other non-random patterns.

Out-of-Control Points–SPC can instantly call out data points falling out of range with preset process parameters.

Equipment Issues–SPC detects deviations between actual and expected performance, indicating equipment problems.

Material Problems–Material defects or inconsistencies not discernible to the eye can often be seen clearly in SPC data.

Manufacturing Process Incompatibilities–SPC data can reveal material/process incompatibilities.

The Many Benefits of SPC

Implementing Statistical Process Control is crucial to MedFab’s ability to identify ways to continually improve efficiency while maximizing consistency and quality. Reducing the risk of defects, errors, and nonconformities leads to better products for patients and increased customer satisfaction.

Get in Touch with MedFab Quality

When quality really matters, you’re in the right place with MedFab.

Get in touch with us today to learn more about our quality assurance program.