Precision CNC Machining

At MedFab Precision Solutions, we specialize in sophisticated CNC machining tailored to the demanding requirements of the medical and aerospace industries, as well as other high-tech OEMs. Our advanced machine shop is equipped with highly precise 3-, 4-, and 5-axis CNC milling stations and multi-axis traditional and Swiss turning centers, ensuring superior quality, efficiency, and repeatability in every project.

High-Precision Multi-Axis Machining

Our extensive multi-axis CNC machining capabilities enable us to produce intricate and complex parts with tolerances as tight as ±0.0005 inches. We leverage:

- Swiss-type turning with deep hole drilling, 8-axis machining, live modular tooling, and tool overlapping functions to minimize cycle times.

- Lights-out manufacturing allows high-speed, unattended production while maintaining precision and consistency.

- Citizen Swiss & Miyano lathes, running multiple tools simultaneously across multiple spindles for optimal efficiency.

- 3-axis and 5-axis milling, enabling us to machine a wide range of materials with exceptional accuracy.

Complex Parts Machined in a Single Cycle

Our CNC machining processes integrate advanced features like adjustable B-axis, prismatic part machining, thread whirling, and automatic bar loaders, allowing us to manufacture highly intricate components in a single setup. By reducing the number of operations required, we optimize efficiency, shorten lead times, and ensure consistent quality across high-volume production runs.

Micro-Machining Expertise

MedFab excels in micro-machining, producing miniature and highly detailed components with extreme precision. Our advanced Citizen-Cincom Swiss-type machines feature high-speed spindles and live tooling (with speeds up to 80,000 RPM) that allow us to achieve ultra-fine tolerances, making us a trusted partner for industries requiring intricate micro-scale parts.

Versatile Material Expertise

MedFab has extensive experience machining in metals and high-performance plastics, including:

Metals

Aluminum, Brass, Platinum, 300 series and 17-4 Stainless Steels, Titanium, MP35N, Nitinol, and more.

Plastics

NPP, Peek, PPS Techtron, Acetal, Ultem, ABS, Delrin, Nylon, Polycarbonate, Teflon, HDPE, and more.

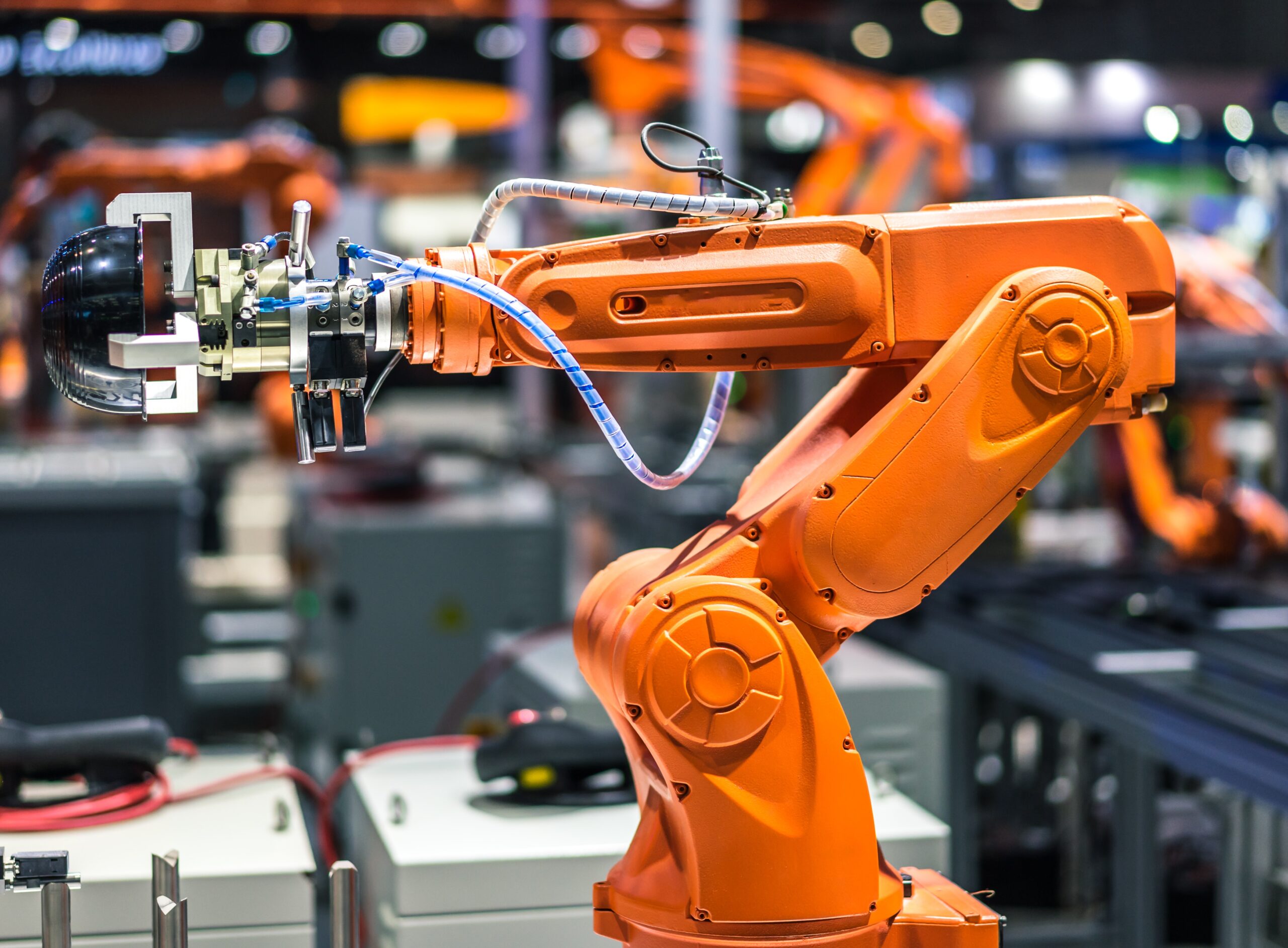

Automation & Robotics

Our team is experienced with:

- Robotic cell creation for increased efficiency and output that meets customer release schedules while reducing costs.

- Programmable Coordinate Measuring Machines (CMMs) to automate inspections of highly complex parts.

Commitment to Quality & Efficiency

MedFab’s CNC machining operations are designed for maximum precision, speed, and efficiency. Whether you require prototyping, low-volume runs, or full-scale production, we have the expertise and technology to deliver high-quality machined components on time and within specification.

Contact MedFab today to discuss your CNC machining needs and discover how our advanced manufacturing solutions can support your next project.