At MedFab Precision Solutions, process engineering is more than a service we provide; it is a tenet we live by. Process engineering is the key to our ability to achieve precision, efficiency, and innovation in everything we do. Whether producing precision parts for medical products or complex components for aerospace and semiconductor markets, MedFab relies on well-defined engineering best practices to optimize throughput without compromising quality.

Design-for-Manufacturing (DFM) & Rapid Prototyping

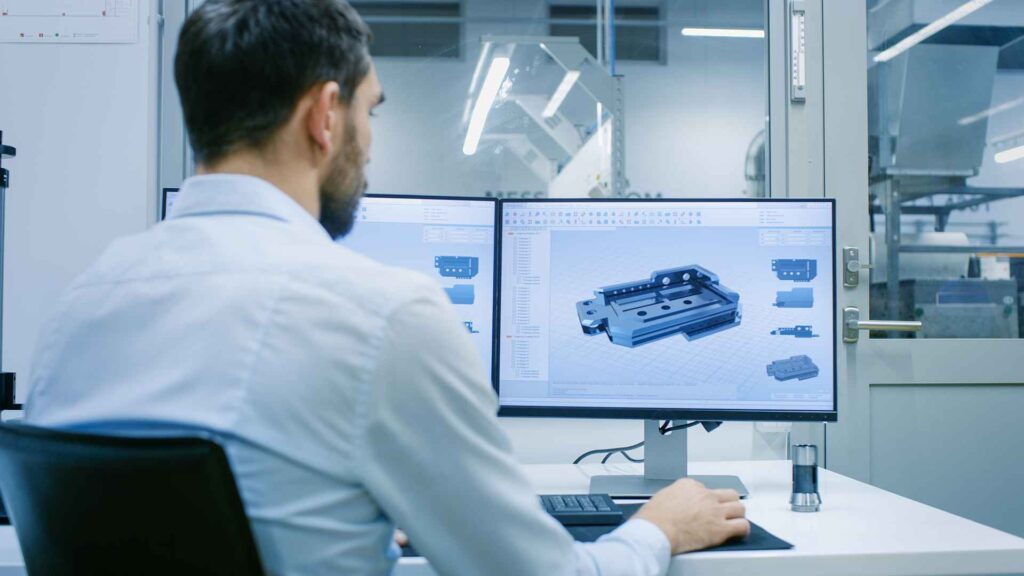

Our Process Engineering team works closely with customers from the earliest stages of development to ensure that every part on the drawing board is optimized from the start for maximum manufacturability. By identifying potential production challenges early, we eliminate the late-stage revisions and delays that can lay waste to your budget and timeline.

We also offer rapid prototyping in production-grade materials, giving MedFab the ability to validate design intent and streamline your transition to full-scale production.

Tailored Workflow Implementation

MedFab builds customized workflows to align with customer requirements, employing proven methods like just-in-time production, Kanban scheduling, or custom hybrid approaches. As an expert in manufacturing in both metals and plastics, MedFab optimizes our shop floor to keep processes separate while optimizing efficiency across all manufacturing cells.

Real-Time Process Monitoring

Continuous monitoring and Statistical Process Control (SPC) are cornerstones of our process engineering strategy. We track critical parameters—such as dimensions, machine performance, and cycle times—to detect trends and catch deviations before they can have a substantial effect on output. This ongoing, real-time insight lets MedFab keep quality consistently high while maximizing machine usage for shorter lead times across the board.

Structured Quality Integration

MedFab integrates process engineering with a robust quality framework. Best practices such as Capability Studies, Failure Modes and Effects Analysis (FMEA), Gage R&R, PPAP, and First Article Inspection are embedded into our production workflows. This structured approach ensures repeatable precision and reduces variability, even in highly complex components.

Continuous Production Feedback

Our commitment to throughput optimization includes daily production tracking meetings and smart manufacturing technologies. Real-time alerts for downtime or out-of-spec conditions allow our teams to respond quickly, balance workloads, and keep production moving on schedule. These feedback loops also provide the data needed to keep production in scale with customer demand.

MedFab Delivers. Precisely.

MedFab’s process engineering best practices are designed to enhance throughput and deliver high-precision components with speed and consistency. By combining early design collaboration, real-time data, and a deep commitment to quality, we provide scalable solutions for medical, aerospace, and semiconductor applications. When you need a partner that can keep pace with complex manufacturing challenges, MedFab delivers results–precisely.