In high-precision industries like medical device manufacturing, intricate parts with close tolerances are the norm, not the exception. At MedFab, we specialize in delivering extremely complex parts and components on tight timelines, at the lowest possible cost. This would not be possible without our extensive expertise in 5-axis CNC machining.

How 5-Axis Machining Expands Our Part Design Capabilities

Traditional CNC machines work on three axes–X, Y, and Z–allowing them to quickly and precisely create simple three-dimensional parts. However, these machines can still be limited in what they can accomplish within a single set-up. In order to get more complex features, operators have to adjust the machine, re-clamping and re-positioning the workpiece so that the interior tooling can actually reach the area that needs to be machined.

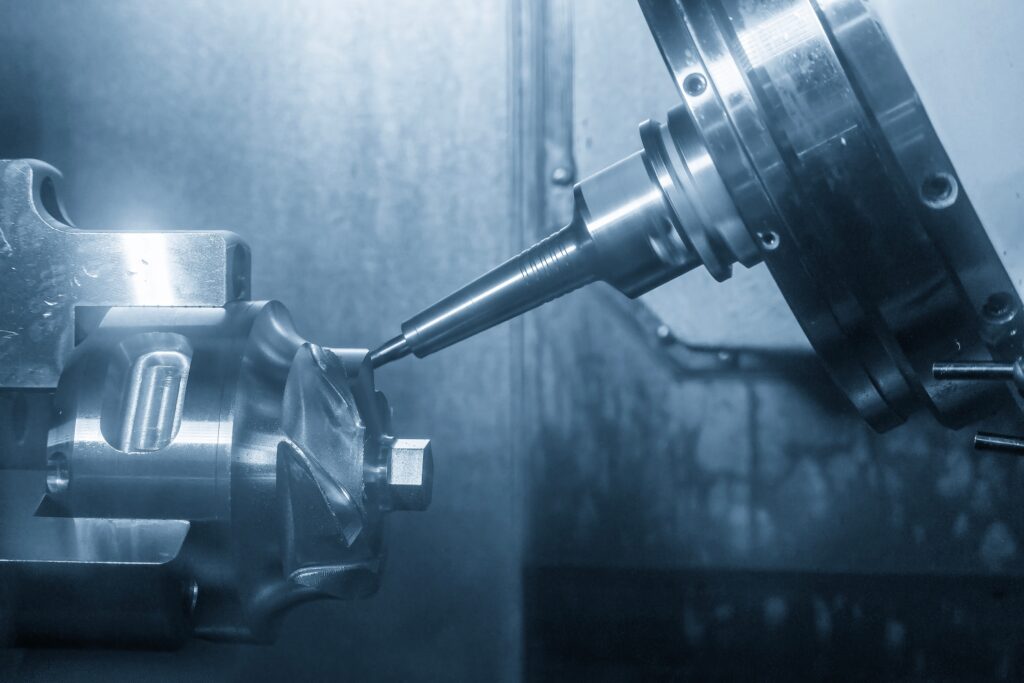

5-Axis machining expands on those capabilities, allowing the tool to rotate around two additional axes. While this seems like a simple upgrade, this additional movement allows the tool to make deep cuts, undercuts, and steep-angled cuts on all sides of the workpiece with very little need for repositioning. So, not only does this type of machining provide the capability to produce more complex parts, like many of those designs found in medical manufacturing, it also reduces set-up and downtime, making the overall production process much more efficient.

This type of manufacturing is especially crucial in medical devices and equipment, where complexity tends to be the norm for component designs. Where a traditional 3-axis CNC machine would require multiple set-ups and cycles to achieve certain features and deeper cuts, a 5-axis machine can typically do the same thing with a single set-up and cycle. For example, we’ve made a variety of surgical tools, custom components for medical and surgical implants, multi-port manifolds, and similarly complicated designs here at MedFab thanks to our expertise in 5-axis machining. These are all components that would be difficult, especially with most medical-grade materials, to achieve efficiently and precisely with traditional machining.

Get Expert 5-Axis Machining Services and More from MedFab

Are your current partners utilizing the latest technology to provide you with the highest quality at the lowest cost? MedFab Precision Solutions is a contract manufacturer supporting a high-tech customer base of medical manufacturers, semiconductor OEMs, and others. They look to MedFab for expertly performed, competitively priced, close-tolerance machining services. For more information, or if you’re interested in requesting a quote, please contact us today to get started.