For industries where even the smallest mechanical deviation can have disastrous consequences, MedFab Precision Solutions has built a reputation for micro machining parts with tolerances measured in micrometers. Achieving sub-0.001″ (25 microns) features consistently necessitates having the most advanced machinery, of course. But machinery alone is not enough. You also need the talent, skill, and expertise to use that machinery to the limits of its potential. Work of the highest precision requires a holistic system calibrated toward precision, process control, and engineering excellence.

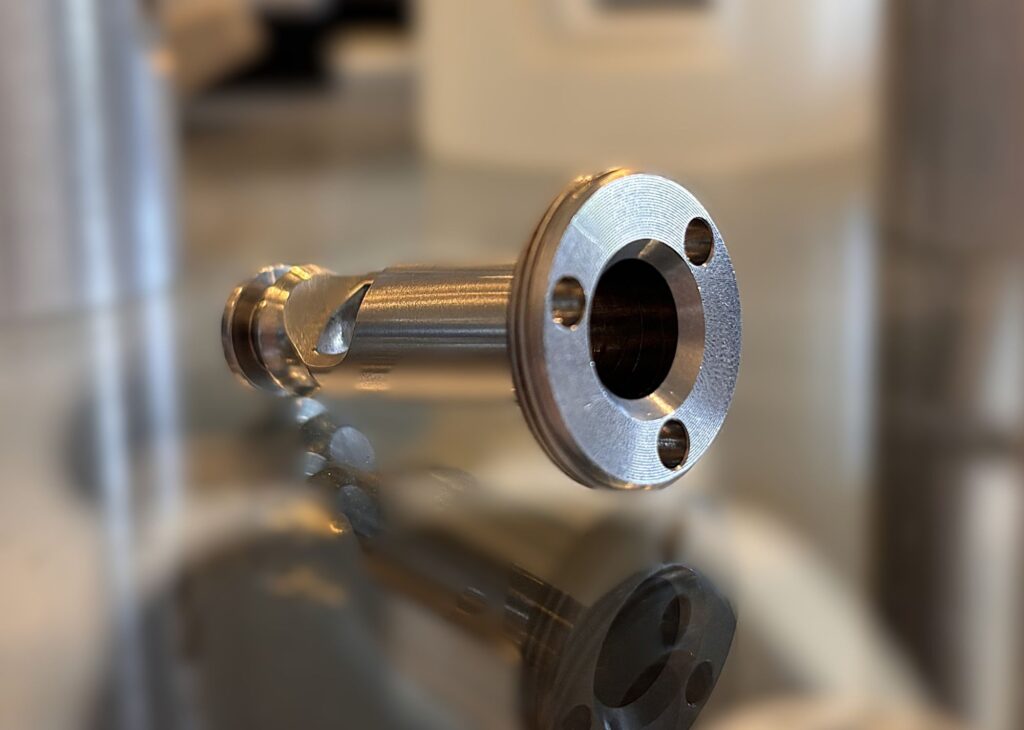

At MedFab Precision Solutions, we specialize in high-precision micro machining, delivering intricate components with exceptional accuracy. Our advanced 3-, 4-, and 5-axis CNC milling and Swiss-type turning capabilities allow us to achieve tolerances as tight as ±0.0002 inches, ensuring the highest level of precision for medical, semiconductor, aerospace, and other tight-tolerance applications.

Ultra-Fine Tooling for Sub-Micron Accuracy

At the heart of MedFab’s capability is the use of ultra-fine cutting tools designed specifically for micro machining. Tool geometry, coatings, and runout must all be optimized to maintain edge sharpness and dimensional control at microscopic scales. Our machining strategies use dedicated tooling paths, slow feed rates, and specialized cutters that remove material cleanly without introducing stress or burrs. These precision tools allow us to create intricate channels, bores, and features smaller than a human hair, all of which are essential for advanced medical, semiconductor, and high-tech applications.

Manufacturing highly intricate, miniature components with unmatched precision requires state-of-the-art machining technologies, such as:

- Multi-axis CNC milling for intricate geometries

- Swiss-type turning for ultra-precise cylindrical parts

- Superior surface finishes to eliminate secondary operations

- High-speed machining for reduced lead times

Vibration-Damping Fixturing for Absolute Stability

Not even the most advanced machine tool can achieve micrometer precision if the workpiece is not held absolutely still. At the micro level, even imperceptible vibrations can obliterate a workpiece. That’s why MedFab engineers custom vibration-damping fixtures to eliminate chatter, distortion, and micro-movement during cutting. By combining rigid clamping with damping materials and precision alignment, we ensure that the workpiece remains absolutely motionless. This fixturing stability is as critical as the machining process itself.

Controlling the Environment to Control Results

Temperature variation is one of the most overlooked sources of dimensional error at the micron level. As with vibrations, even the slightest change in temperature is magnified when working at the sub-micron scale, where thermal expansion in either the machine or the workpiece can take the operation out of tolerance. MedFab addresses this with strict environmental controls, including climate-regulated production areas and thermal compensation strategies integrated into our CNC systems. By maintaining constant conditions and accounting for thermal drift, we ensure that tolerances are preserved from start to finish.

Precision Beyond the Machine

These measures are complemented by rigorous in-process metrology, documented quality protocols, and operator expertise. From prototype to full-scale production, our team treats micrometer accuracy as a baseline standard.

At MedFab Inc, we recognize that achieving micrometer precision isn’t just a matter of adding another step, machine, or skillset to the typical processes involved in standard machining. Micromachining requires a fusion of ultra-fine tooling, vibration-resistant fixturing, and tightly controlled environments. MedFab’s micro machining system enables us to deliver consistent, reliable sub-0.001” features that allow our customers to push the limits of innovation ever further.